Telehandler 2706 - Efficient compactness

If dealing with stacking heights of almost 6.0 m, the 2706 telehandler is the ideal solution. With a payload of 2.7 t, even the heavy loading procedures do not pose a problem. With a number of option variants, the 2706 is the true all-rounder on the construction site. The two selectable cabin heights make it possible to obtain even more of an overview, while enabling application in low buildings.

Telehandler 2706

Benefits at a glance

- Compactness: The compact dimensions enable efficient work in confined spaces, for example in underground garages

- Modern operating concept: 7" LCD display, all-in-one joystick and jog dial control element for simple machine control

- Motor: Economical consumption and high torque, exhaust gas aftertreatment with DOC and DPF

- Travel drive: Hydrostatic travel drive without gearshift with up to 40 km/h travel speed

- Smart Attach: Hydraulic attachments can be changed quickly, easily and safely thanks to the optional fully hydraulic quick-change plate

Highlights

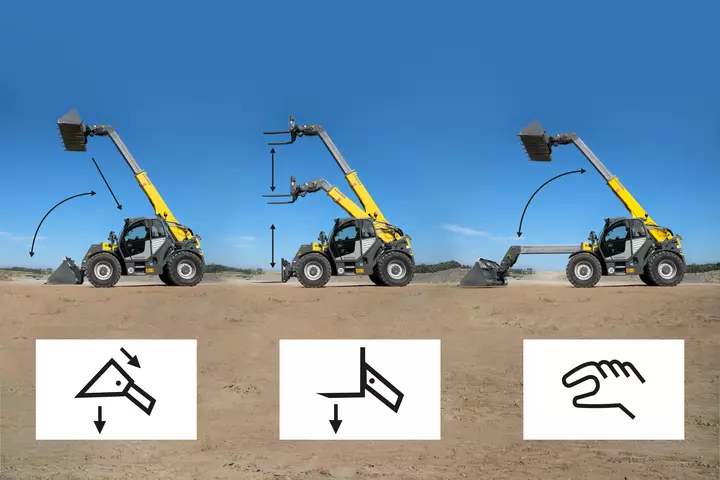

Smart handling

- Relief for the driver through semi-automated movement of the loading system

- Increased safety, as the vehicle is prevented from tipping over lengthways

- Increase in efficiency as a result of setting the machine to the relevant working conditions

Two selectable cabin heights

- Improved all-round visibility for the driver thanks to the elevated cab

- Low cab variant for applications with limited clearance heights

7" LCD display

- All relevant machine data at a glance summarised on the display

- Operating and setting the machine’s parameters easily and intuitively using the jog dial

- Safe jog dial operation possible, even when driving

360° all-round visibility

- Excellent 360° visibility due to the large glazed areas and narrow cabin pillars

- Panoramic front windscreen for an ideal view of the attachment

- High degree of work quality and safety as the work area can be optimally viewed

Color-coded switches

- Uniformed color scheme for hydraulic, electric, driving, and safety features

- Increased safety due to minimized danger of mixing up switches

- Operating concept that reaches across all models to simplify the handling of the fleet

Further Highlights

-

Please note that the product range may vary depending on the country.

-

The technical data of the products may vary accordingly with the selection of different options.