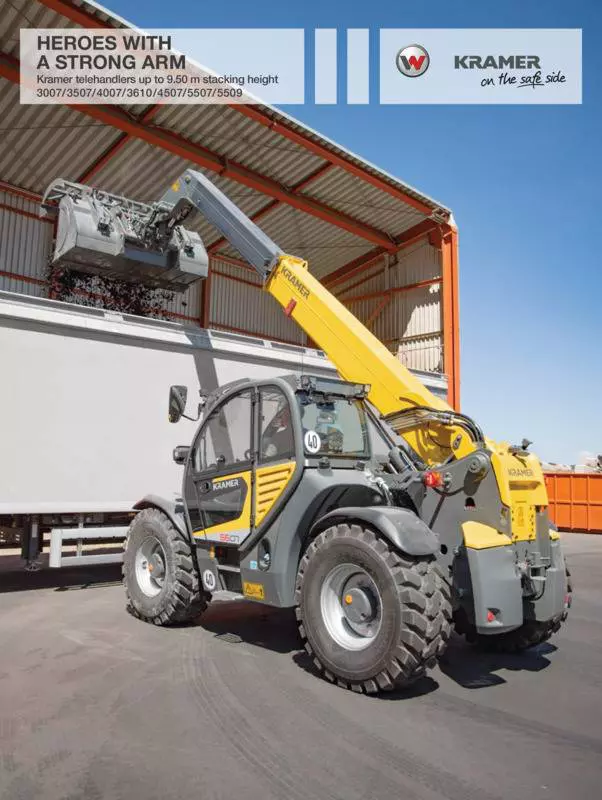

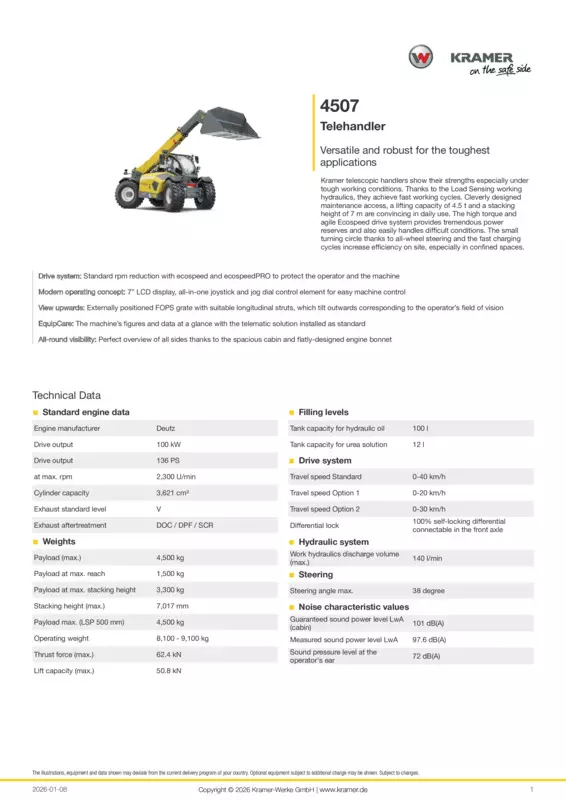

Telehandler 4507 - Versatile and robust for the toughest applications

Kramer telescopic handlers show their strengths especially under tough working conditions. Thanks to the Load Sensing working hydraulics, they achieve fast working cycles. Cleverly designed maintenance access, a lifting capacity of 4.5 t and a stacking height of 7 m are convincing in daily use. The high torque and agile Ecospeed drive system provides tremendous power reserves and also easily handles difficult conditions. The small turning circle thanks to all-wheel steering and the fast charging cycles increase efficiency on site, especially in confined spaces.

Telehandler 4507

Benefits at a glance

- Drive system: Standard rpm reduction with ecospeed and ecospeedPRO to protect the operator and the machine

- Modern operating concept: 7” LCD display, all-in-one joystick and jog dial control element for easy machine control

- View upwards: Externally positioned FOPS grate with suitable longitudinal struts, which tilt outwards corresponding to the operator’s field of vision

- EquipCare: The machine’s figures and data at a glance with the telematic solution installed as standard

- All-round visibility: Perfect overview of all sides thanks to the spacious cabin and flatly-designed engine bonnet

Highlights

Color-coded switches

- Uniformed color scheme for hydraulic, electric, driving, and safety features

- Increased safety due to minimized danger of mixing up switches

- Operating concept that reaches across all models to simplify the handling of the fleet

7" LCD display

- All relevant machine data at a glance summarised on the display

- Operating and setting the machine’s parameters easily and intuitively using the jog dial

- Safe jog dial operation possible, even when driving

360° all-round visibility

- Excellent 360° visibility due to the large glazed areas and narrow cabin pillars

- Panoramic front windscreen for an ideal view of the attachment

- High degree of work quality and safety as the work area can be optimally viewed

Further Highlights

-

Please note that the product range may vary depending on the country.

-

The technical data of the products may vary accordingly with the selection of different options.