Wheel Loader 5065 - Rugged on the outside and intelligent on the inside.

The all-wheel drive 5065, which has become known as the "650", is a model in the 5 Series and is synonymous with compactness and maneuverability. The bucket volume of 0.65 m³ to 1.1 m³ and the standard Kramer quick-release plate allow unbeatable flexibility for any application. The undivided frame and proven all-wheel steering ensure maximum stability and maneuverability on uneven terrain. Especially in road construction, horticulture and landscaping, the machine is easily able to lift a stone pallet - a special feature in this size class.

Wheel Loader 5065

Benefits at a glance

- Flexible use: A bucket volume from 0.65 m³ to 1.1 m³ depending on material density.

- Safety: The convenient and intuitive operation of all functions creates safety, even for novice drivers.

- Constant payload: Due to the undivided frame, the vehicle has an unchanged vehicle length which enables a constantly high payload.

- Environmentally friendly engine technology: One 35 kW engine with exhaust stage V, as well as DOC and DPF.

Highlights

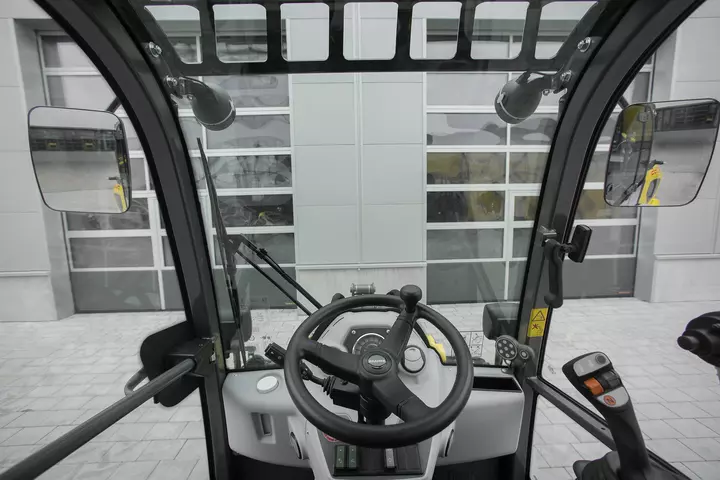

360° all-round visibility

- Excellent 360° visibility due to the large glazed areas and narrow cabin pillars

- Panoramic front windscreen for an ideal view of the attachment

- High degree of work quality and safety as the work area can be optimally viewed

Color-coded switches

- Uniformed color scheme for hydraulic, electric, driving, and safety features

- Increased safety due to minimized danger of mixing up switches

- Operating concept that reaches across all models to simplify the handling of the fleet

Easy maintenance access

- Easy access to the engine compartment thanks to the wide-opening hood

- Optimum accessibility of all important components for checking fill levels

- Quick implementation of service work thanks to vertically mounted filters and additional maintenance openings

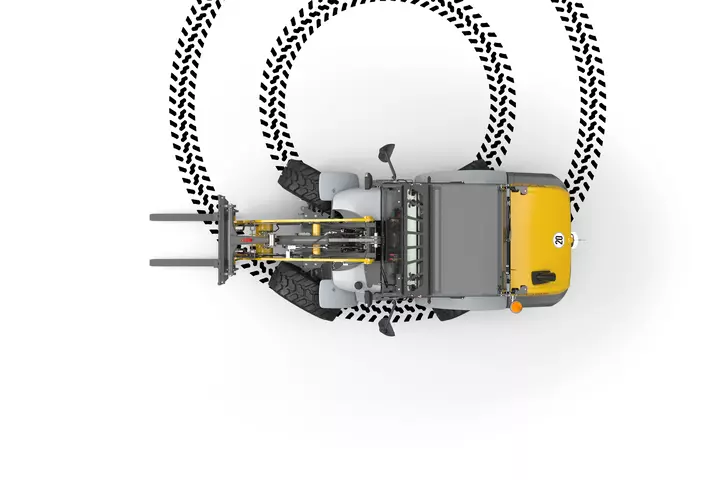

All-wheel steering

- High stability even at full steering lock thanks to the undivided frame

- Maximum maneuverability thanks to steering angles of up to 40° on both the front and rear axles

- Consistent payload independent of the steering angle for constant leverage ratios

Further Highlights

-

Please note that the product range may vary depending on the country.

-

The technical data of the products may vary accordingly with the selection of different options.