Wheel Loader 5095 - The down-to-earth powerhouse.

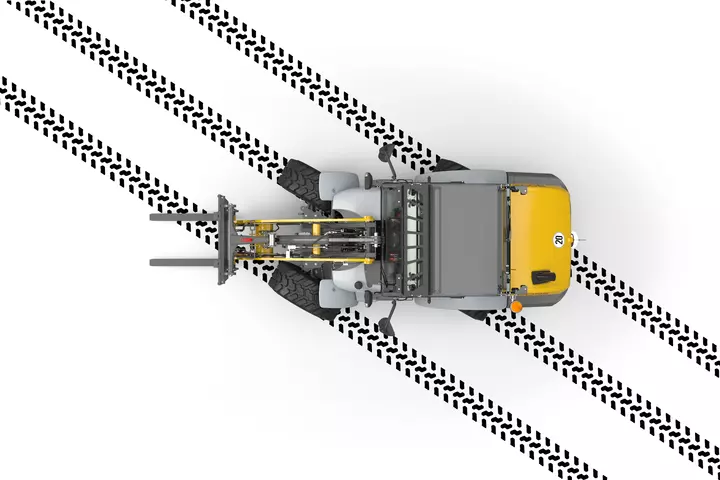

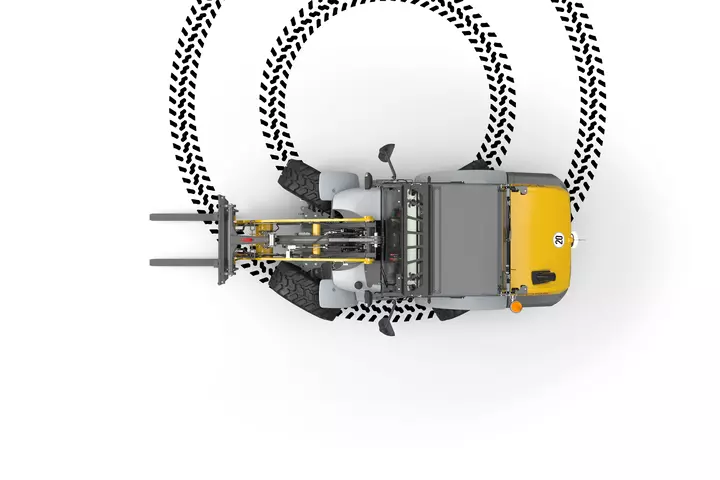

The 5095 machine impresses with its dynamic all-wheel drive and high payload. The bucket volume of 0.95 m³ to 1.5 m³ with low overall height distinguishes the machine in this size class. The efficient high-pressure travel drive enables high thrust forces. In addition, the optional high-speed gear offers further versatile applications.

Wheel Loader 5095

Benefits at a glance

- Bucket volume: The bucket volume of 0.95 m³ to 1.5 m³ with a headroom of less than 2.5 m distinguishes the machine in this size class.

- Speed: The 5095 can be equipped with the 30 km/h fast gear.

- Long loading system: En extended mast is available, which makes the machine more flexible in terms of reach and pile height.

- Exhaust gas stage V: Exhaust gas aftertreatment takes place through DOC and DPF.

- Bucket volumes: The bucket volumes of 0.95 m³ to 1.5 m³ with a height of less than 2.5 m characterise the machine in this size class